This example demonstrates how to build a transfer function-based DC motor speed closed-loop control system, employing feedforward compensation and anti-windup PID control strategies to achieve high-precision, fast-response motor speed regulation.

The system uses a dual-channel drive architecture to eliminate steady-state error while ensuring dynamic performance.

Theoretical Basis

DC Motor Transfer Function Modeling

A DC motor is composed of an armature circuit coupled with a mechanical rotating subsystem.

Armature Circuit Voltage Equation:

Mechanical Torque Balance Equation:

Where is the drive voltage, is the rotor angular velocity, is the torque constant, is the back-EMF constant, is the moment of inertia, and is the friction coefficient.

Transfer Function Derivation: Eliminating the current variable yields the standard second-order form:

Feedforward + PID Dual-Channel Control

The system adopts a parallel drive structure, balancing response speed and disturbance rejection.

Feedforward Channel:

Directly generates the baseline drive voltage based on the reference speed, achieving fast response without overshoot.

PID Channel:

Compensates for model errors and external disturbances through Proportional-Integral-Derivative regulation.

Total Control Output:

Anti-Windup Mechanism

When the control voltage exceeds the saturation limit, the anti-windup loop is activated to suppress integrator saturation:

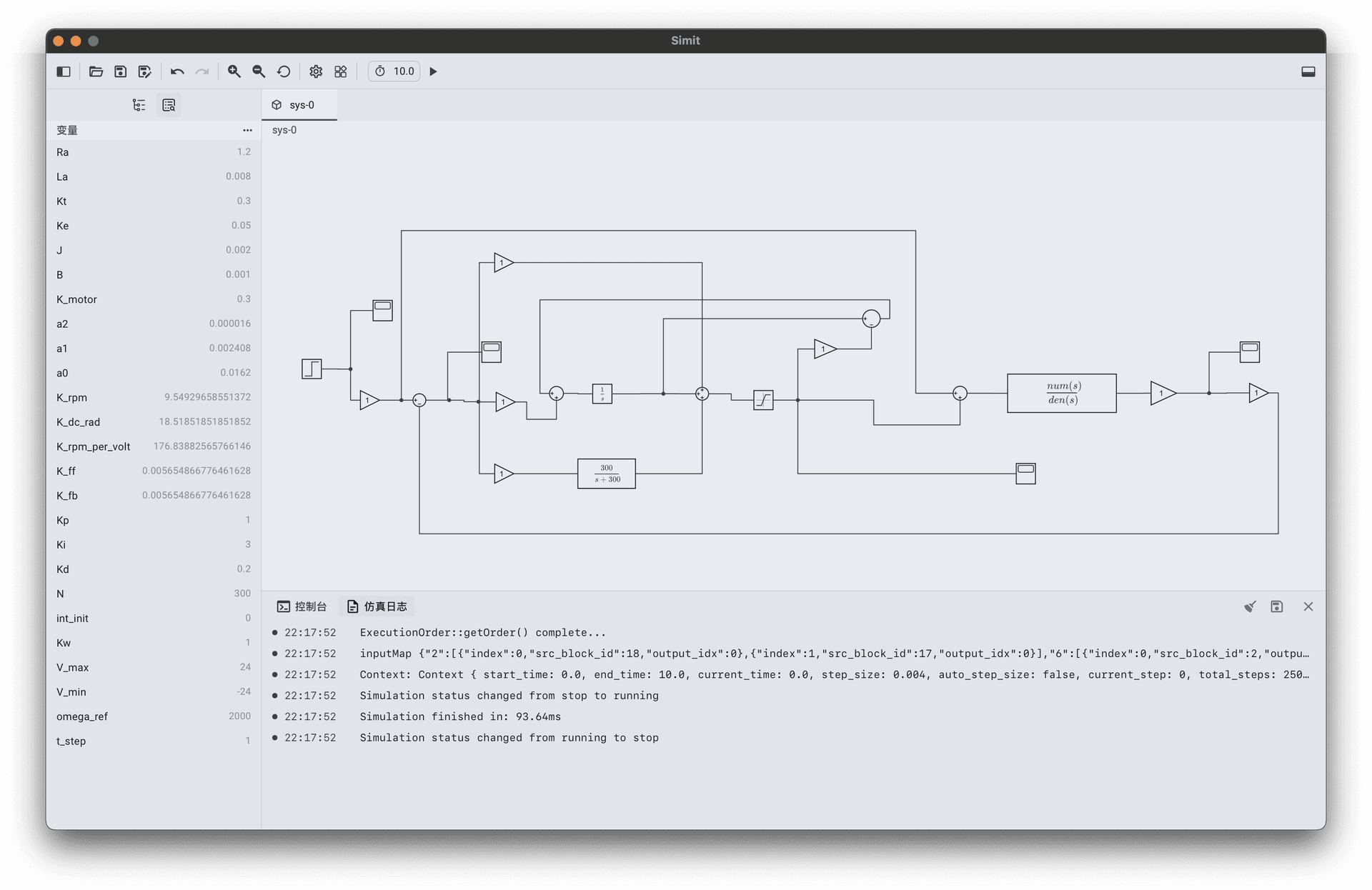

Simulation Model

Model Hierarchy

The system uses a modular design, as shown below:

Core Block Parameter Quick Reference

| Block Function | Parameter | Value | Description |

|---|---|---|---|

| Target Speed | omega_ref | 2000 | Target Speed (rpm) |

t_step | 1.0 | Step Time (s) | |

| Motor TF | Kt | 0.3 | Torque Constant (N·m/A) |

Ke | 0.05 | Back-EMF Constant (V/(rad/s)) | |

Ra | 1.2 | Armature Resistance (Ω) | |

La | 0.008 |

Note: K_rpm_per_volt = Kt / (Ra*B + Kt*Ke) * 60/(2*pi) is the DC gain of the motor (rpm/V), automatically calculated from raw parameters.

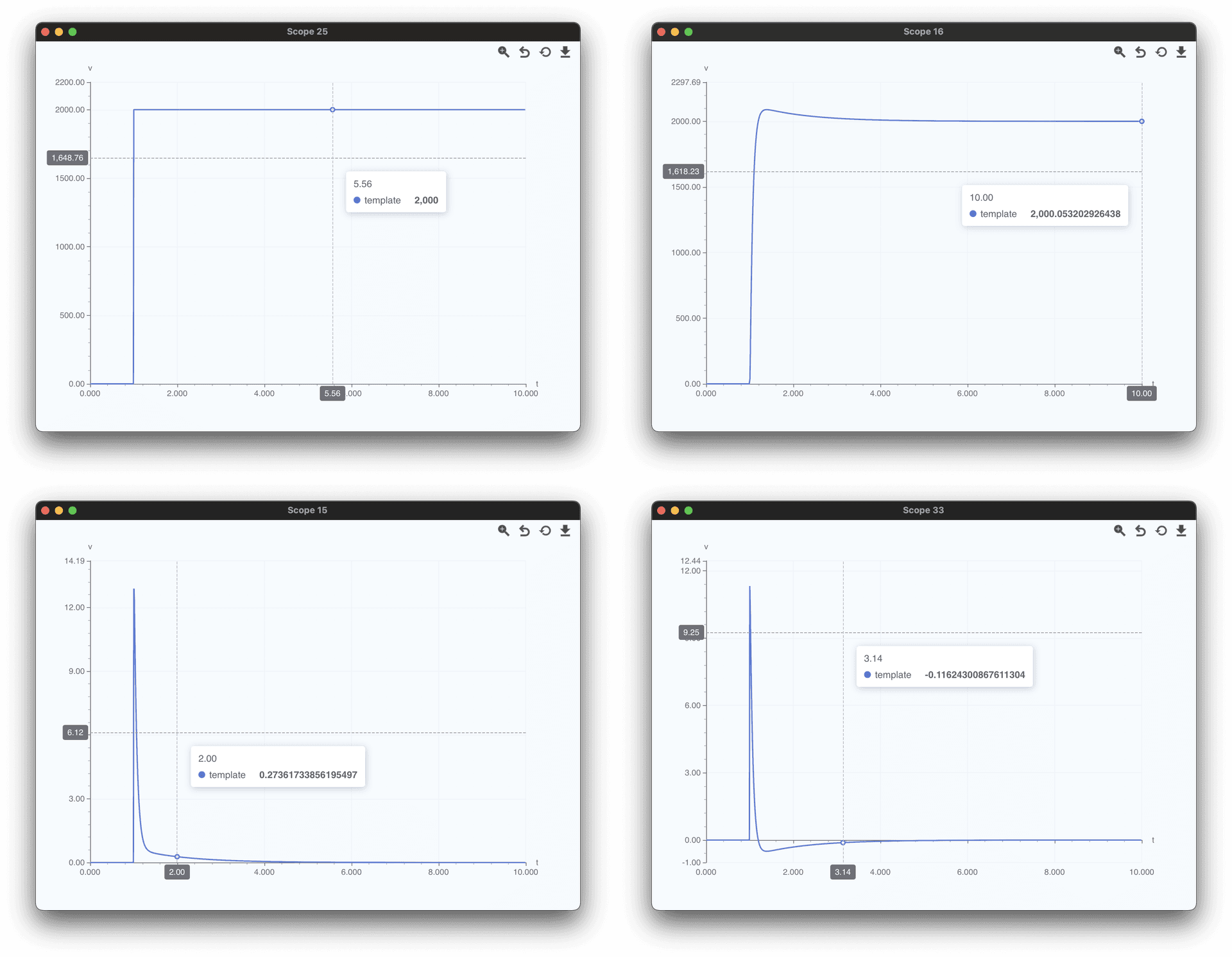

Performance Metrics

Steady-State Performance

- Steady-State Error: ≤ 1% × Target Speed

- Target: 2000, Steady-State: 2004

- Voltage Utilization: ≤ 70% (Reserved dynamic margin)

- Limit: 24V, Max Control Voltage: ~13V

Dynamic Performance

- Overshoot: ≤ 5%

- Settling Time: ≤ 1.5s (Within ±2% error band)

- Anti-Windup Recovery: ≤ 0.3s

Results Analysis

Typical Response Process:

- 0-0.2s: Feedforward channel dominates, approaching target speed rapidly.

- 0.2-1.0s: PID channel fine-tunes, integrator eliminates residual error.

- >1.5s: Enters steady state, PID output approaches zero, feedforward maintains speed.

Observed Effects:

- Speed tracks the setpoint smoothly with static error < 10 rpm.

- Voltage output is smooth with no significant saturation.

- Anti-windup mechanism intervenes quickly during load steps.

Applications

- Engineering Prototyping: Development of 24V DC motor speed control systems.

- Algorithm Research: PID parameter auto-tuning, intelligent anti-windup strategies.

Configuration Code

# 1 Motor Physical Parameters (SI Units)

# Modify these parameters to adapt to different motors

Ra = 1.2; # Armature Resistance (Ω) - Affects steady-state voltage demand

La = 0.008; # Armature Inductance (H) - Affects electrical response speed

Kt = 0.3; # Torque Constant (N·m/A) - Affects torque output capability

Ke = 0.05; # Back-EMF Constant (V/(rad/s)) - Key: Smaller Ke means higher max speed

J = 0.002; # Moment of Inertia (kg·m²) - Affects mechanical response speed

B = 0.001; # Friction Coefficient (N·m/(rad/s)) - Affects low-speed performance

# 2 Transfer Function Coefficient Calculation

# Automatically calculate numerator and denominator based on physical parameters

K_motor = Kt; # TF Numerator = Torque Constant

a2 = La * J; # 2nd-order term: Electro-mechanical coupling

a1 = Ra * J